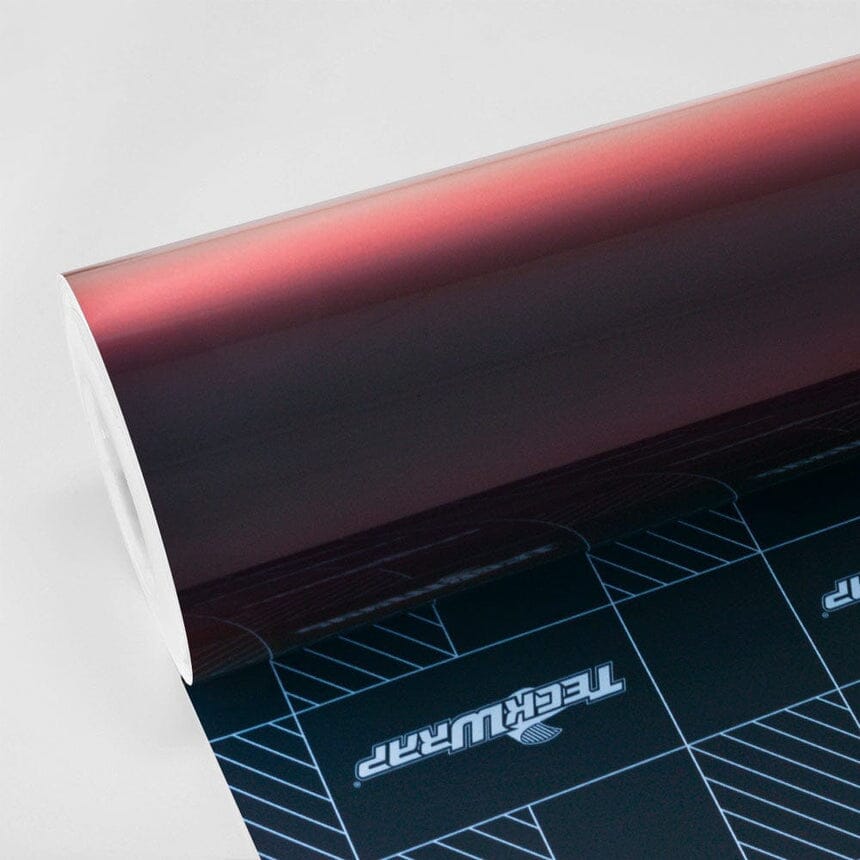

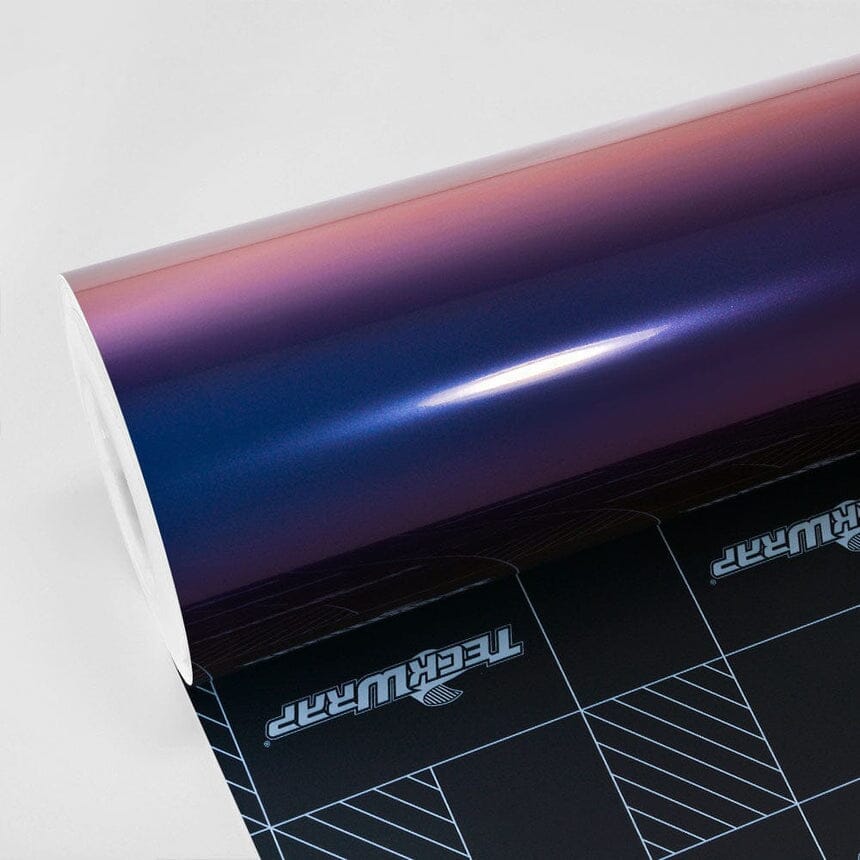

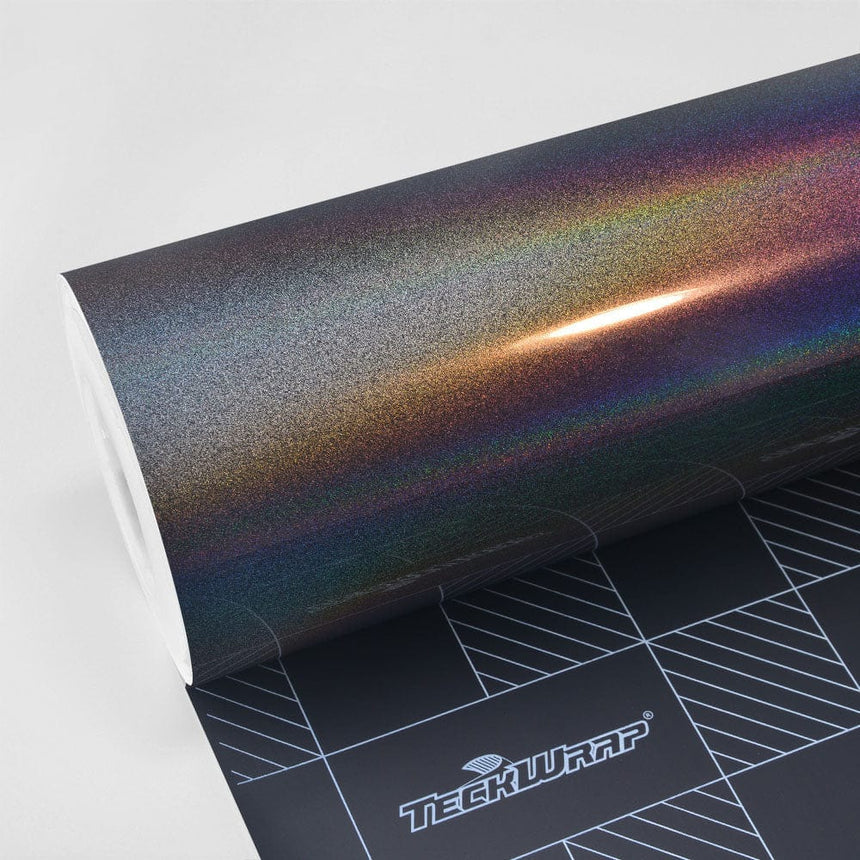

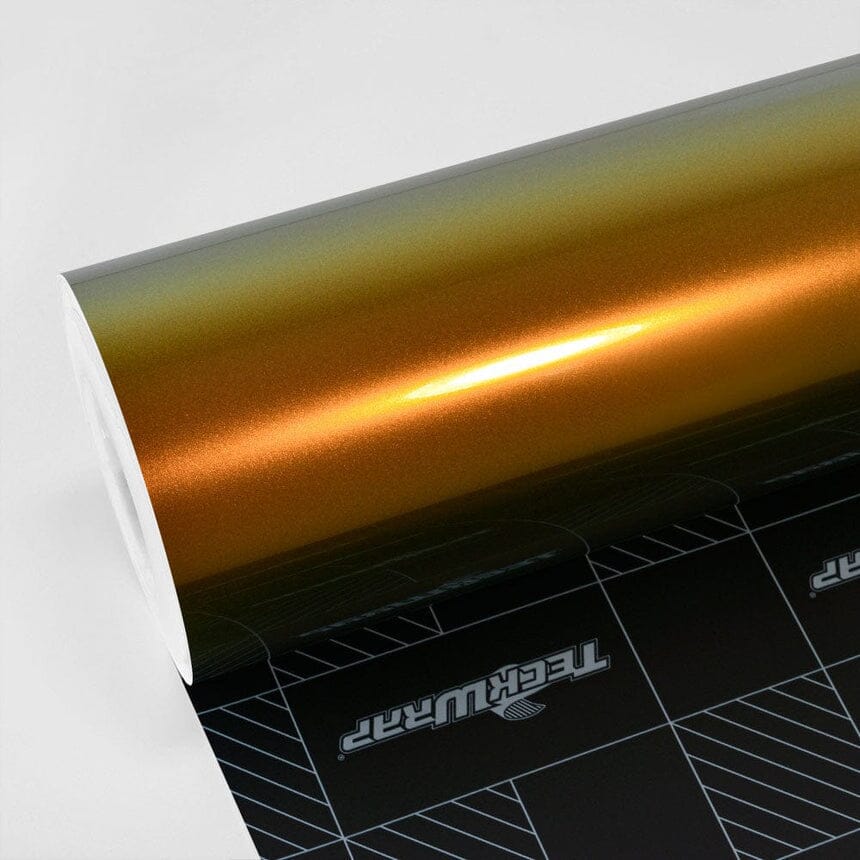

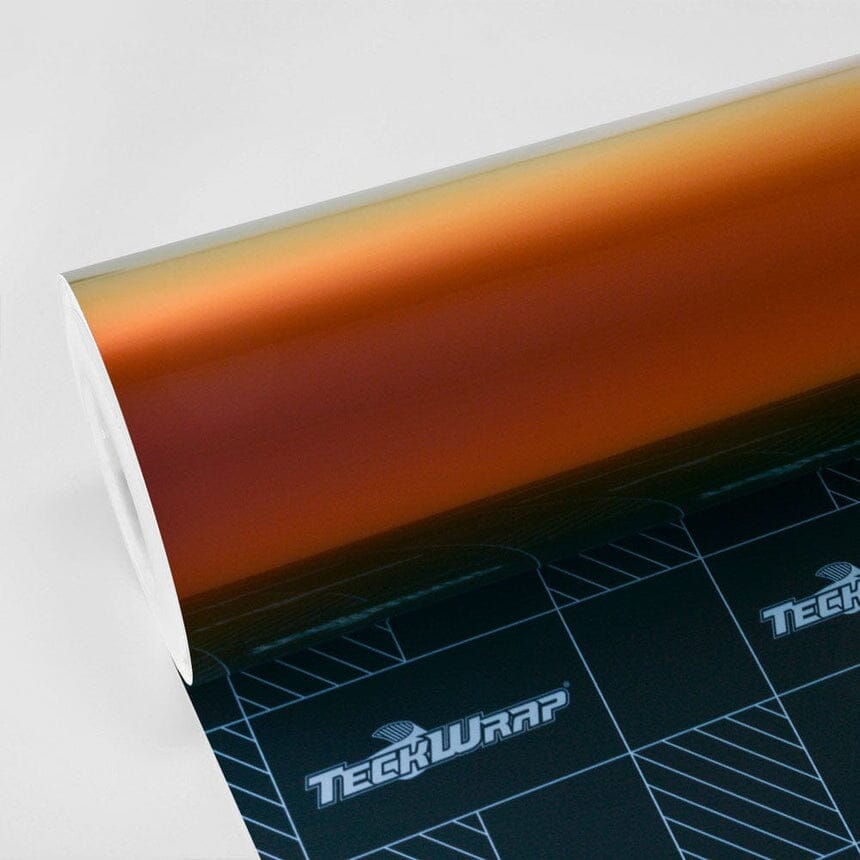

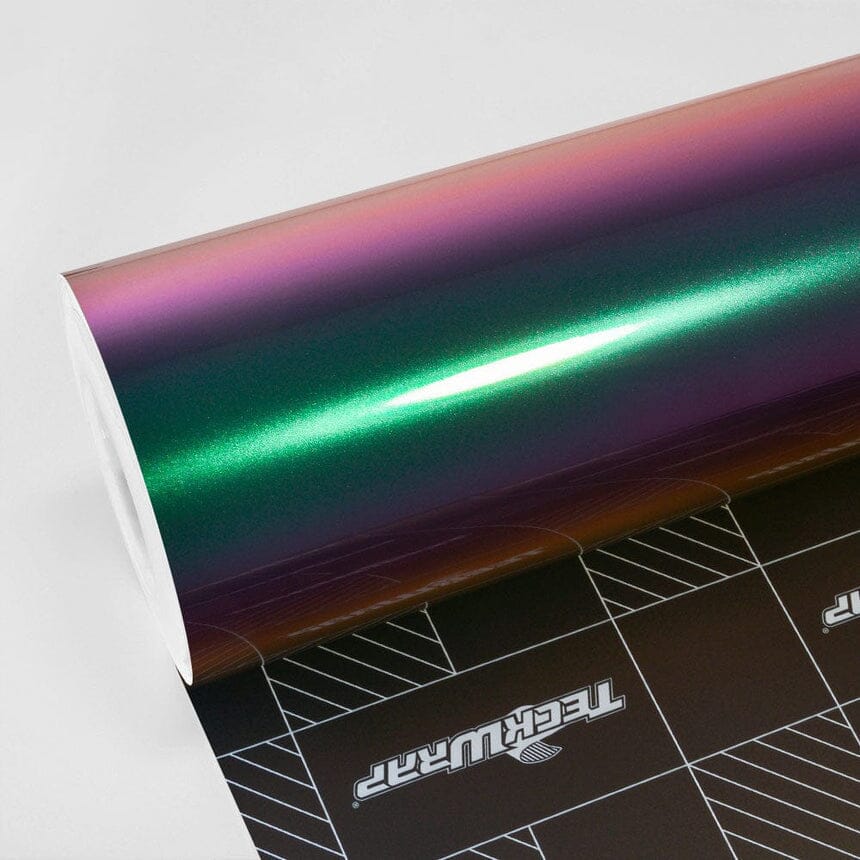

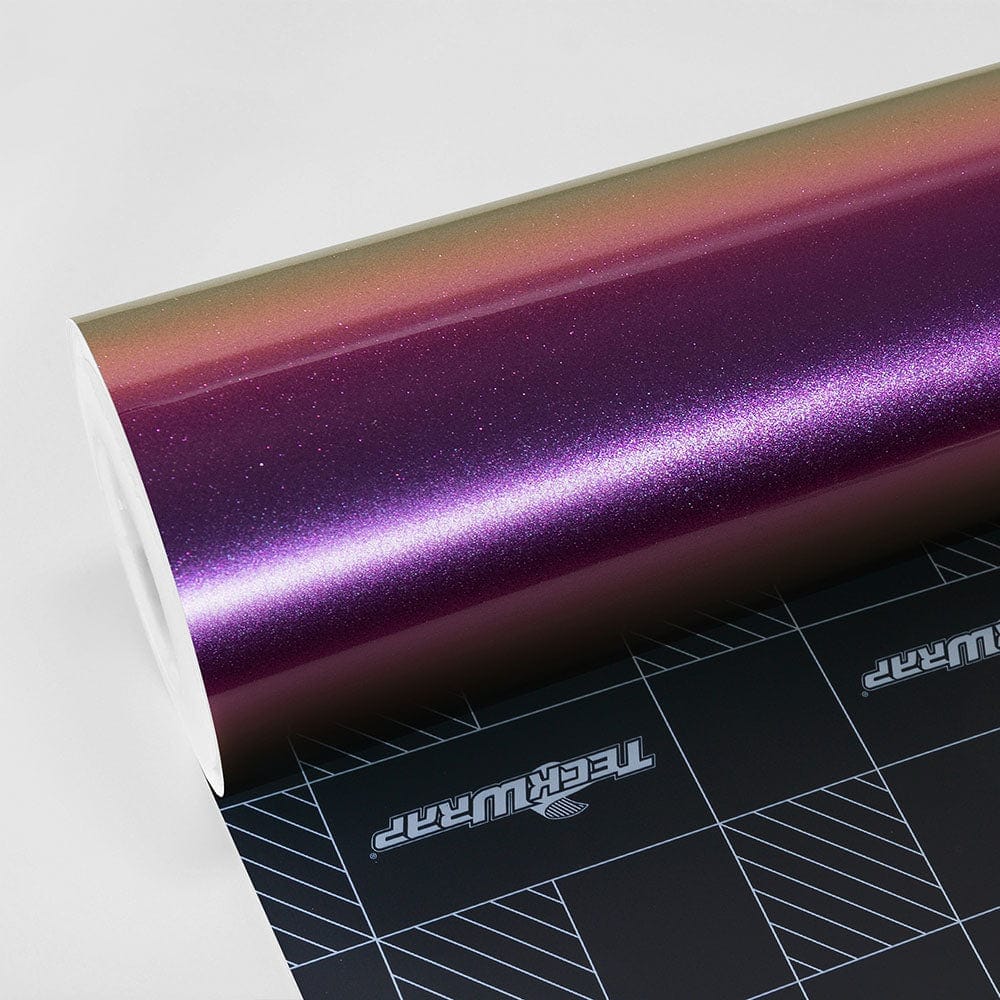

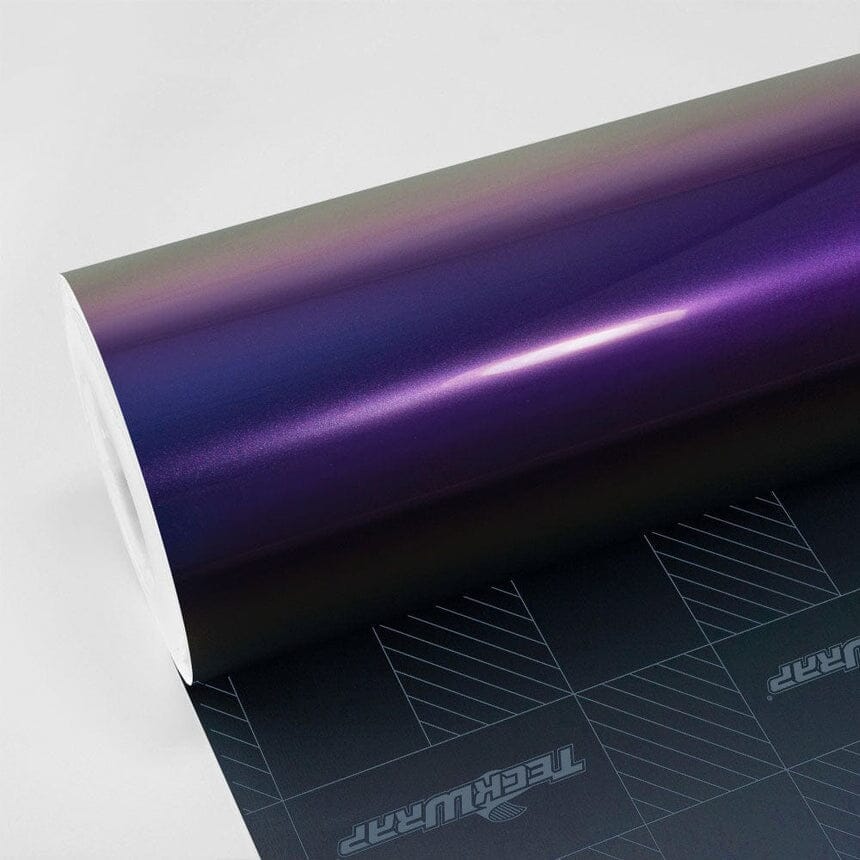

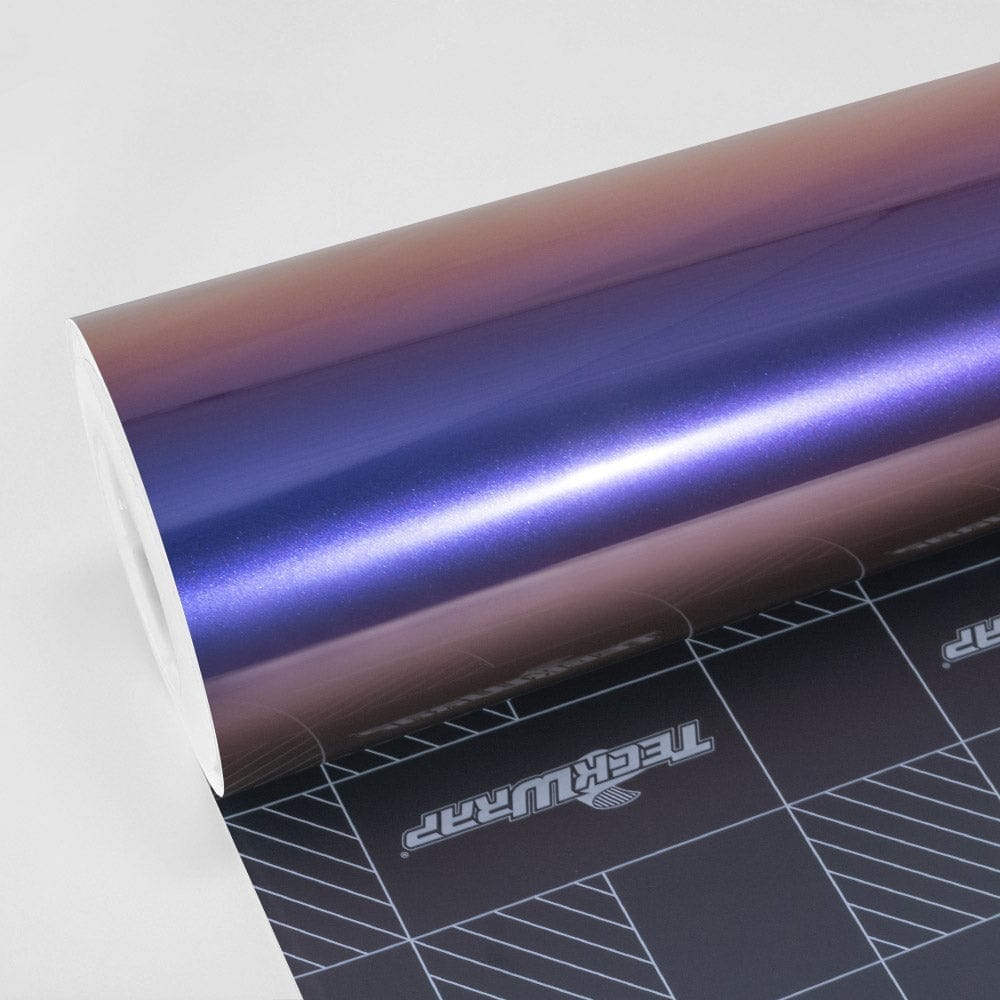

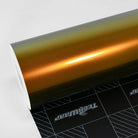

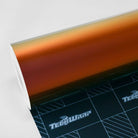

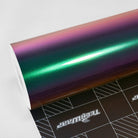

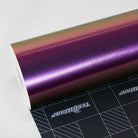

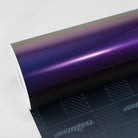

Gloss Color Shift Metallic - RD Series

Couldn't load pickup availability

DESCRIPTION

With a collection of five stunning colors, TeckWrap offers you this series of color-shifting vinyl wrap (Rainbow Drift), which gives your vehicle a unique, stylish finish. As a proud supplier, TeckWrap has plenty of film selections that have good conformability and durability. The material is stretchable enough to wrap every edge and recessed area easily. And the adhesive is safe without giving you any trouble when uninstalling. The better thing is, these vinyl wraps from TeckWrap are all high quality but reasonable and affordable prices.

SPECIFICATIONS

Conformable material with stable color pigments. Suitable for full car wrapping (or any other smooth or curved surface).

The thickness of film: 0.16mm

The thickness of film with release liner: 0.32mm

Type of film: High grade polymeric multilayered calendared vinyl film with air release channels

Colors: Winered Nebula, Ibiza Sunset, Iris Purple Gem, Peacock Green, Northern Aurora

Width & Length: 1.52m*18m (59.8"* 708,6", 4.98ft*59ft, 1.66yd* 19,6yd)

Series: 190 series

Adhesive: Solvent polyacrylate

Adhesive performance properties: (1mil adhesive on 1mil material, bounded to stainless steel panel) 180°Peel (PSTC-101), 20-minute bond – 2.2 lb/inch, 24-hour bond – 3.5 lb/inch

Release liner: Kraft white silicone-coated, paper with a double-sided polyethylene coating

Storing period (shelf life): 2 years if stored in +10°С to +20°С, relative humidity 50%, in original package, away from direct sunlight, clean and dry place

Avg. indoor life: 4 years when followed rules of application and usage

Avg. outdoor life: 3 years when followed rules of application and use

Application: from +17°С to +25°С, usage from -55°С to +65°С

Dimensional stability: shrinkage less than 3%(matte), 4% (glossy)

Plastification: between 27%-35%

Breaking Strength: 22.7 N/10mm (Average) Test Method: ASTM D3759/D3759M-057.4 N/10mm (Average)

Light Ageing in UV Exposure: Test Method: ASTM D4329-13 Cycle A & ISO 105-A02:1993/Cor.2:2005, Test result: 5

Exposure cycle: ASTM D4329-13 cycle A, Lamp type: UVA-3408h UV at (60±2.5)℃ BPT, 0.89 W/ (m2•nm)@340nm, 4h condensation at (50±2.5)℃ BPT, Exposure duration: 49h

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, IRR heater

Application method: Standard methods for calendared films. No overstretching. Post heating

Post-heating temperature: 110℃ flat surfaces, 130℃ curves, and overlaps

Cure time: 24 hours above 10℃

Aftercare: PH neutral, Avoid wax or solvents

Directional: yes

Tools: soft squeegees with buffers

Important note: The images, colors, and finishes on screen are approximate. For the real representation of the product always check the color swatch. Rolls from the same production LOT number should be used for completing a wrap job as a slight batch to batch variation of color may occur. The film may scratch during the application, or during a day in and out use. The scratching of the film is not covered by the warranty.